Machining

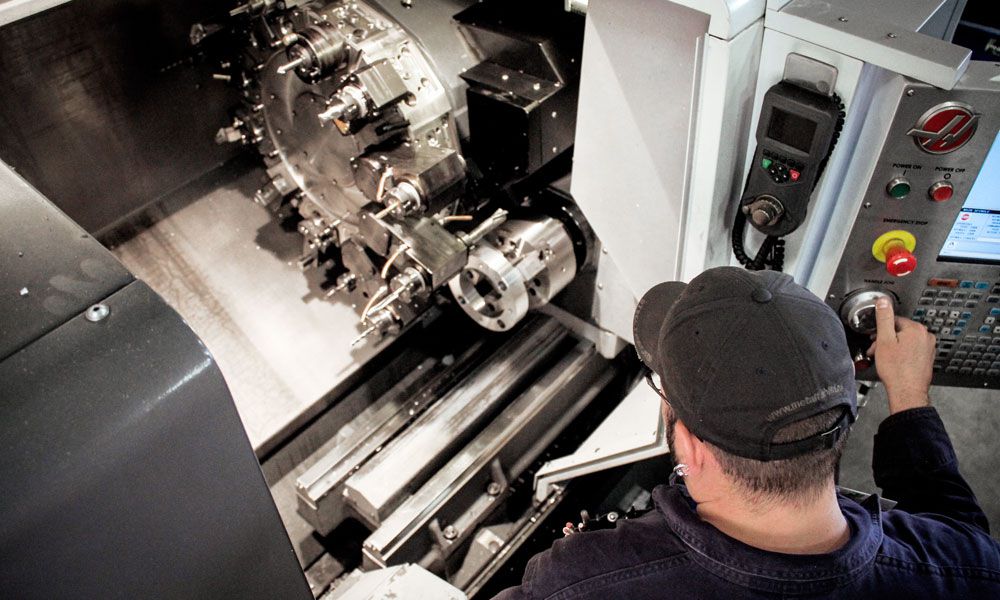

Metal Fab has a 10,000 square foot Conventional and CNC machine shop located within the main warehouse. Using the latest Mastercam software the machine shop features a storehouse of precision equipment such as; a Haas CNC Dual-Spindle turning center, with a Y-Axis that can turn, bore, thread, groove, and drill your machined parts axially and radially. Metal Fab also has Two Milling Machines with a 4th Axis and two Lathes that can handle your highly accurate and detailed production needs.

- EXPLORATION DRILL MAST

- ROD BREAKERS

- HEAVY MACHING

- COMPLETED IN HOUSE AT METAL FAB LTD.

- CNC MACHINING

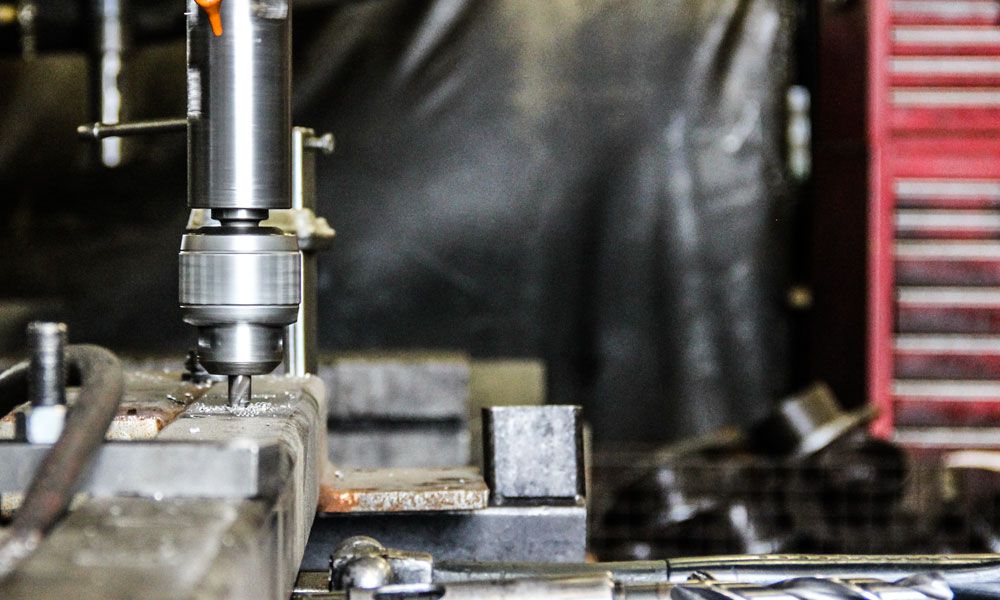

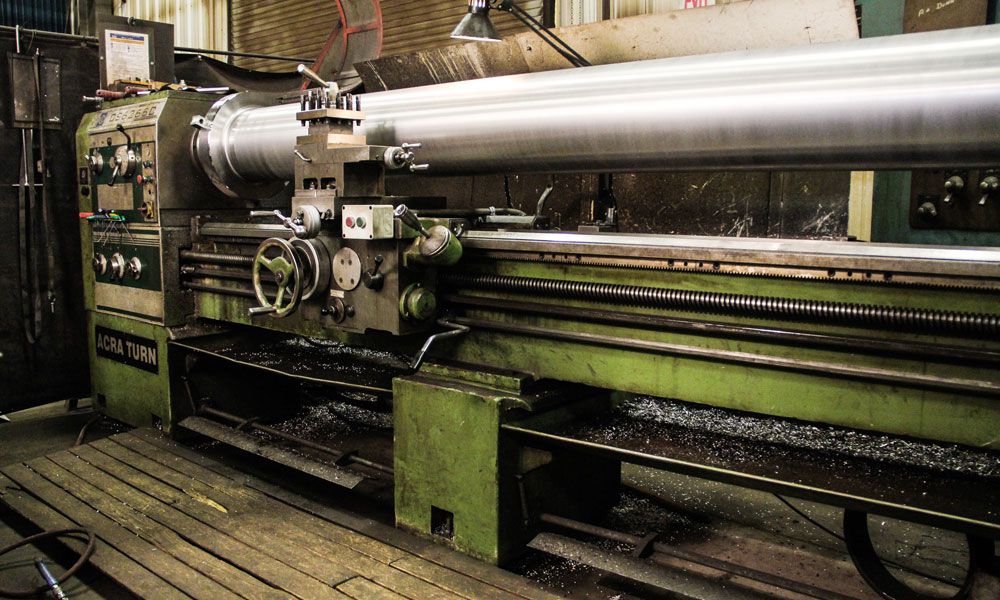

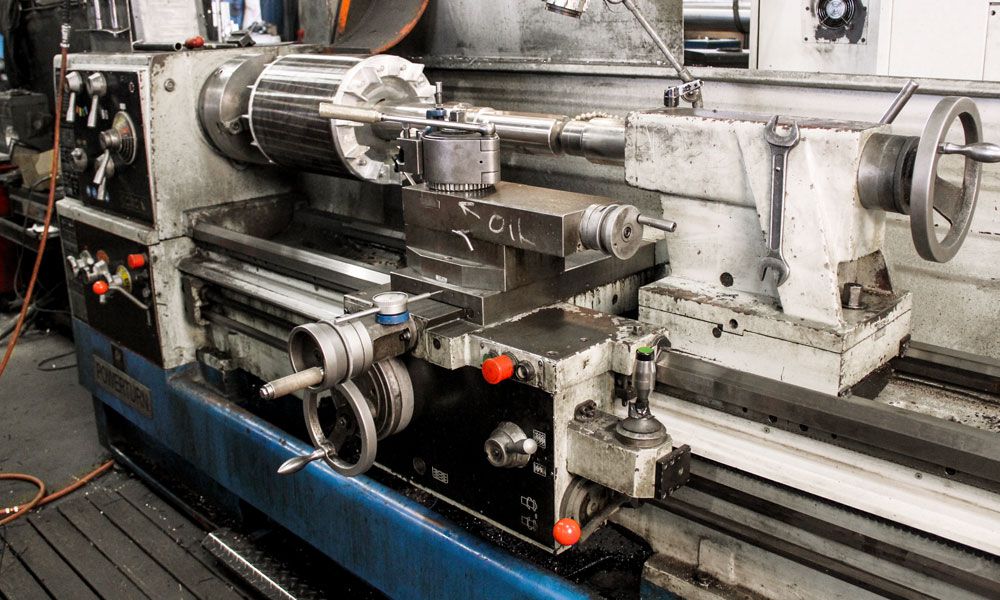

CONVENTIONAL MACHINING EQUIPMENT

Metal Fabs’ Conventional Machine shop has a Turning Capacity up to 24 inches. It excels in its milling and boring capabilities. Our custom machining offers highly precise production parts with tolerance as tight as plus/minus .0002” of an inch! We service both heavy and light equipment repairs and rebuilds.

- 3 radial arm drills

- 3 horizontal boring mills

- 5 engine lathes

- 4 conventional mills

- Broaching machine (24” Stroke)

CNC Machining Equipment

Metal Fab machines many types of materials including stainless, low to high carbon steels, copper, brass, aluminum and plastics. Our modern facility combined with a team of experienced personnel provides superb customer service and high-quality parts that meet today’s demanding schedules at competitive prices. For our advanced projects, we have access to quality equipment from both Doosan and Argmachine Techno Co.

Our CNC machine equipment line includes:

- 3 Doosan 300, CBC 3 axis lathe

(3.5” spindle bore) - Doosan CNC 60/40 4 axis vertical mill

- Doosan 400, CNC lathe

(4-5/8” spindle bore) - AGMA 158 (60-40 bed size) 4 axis vertical mill